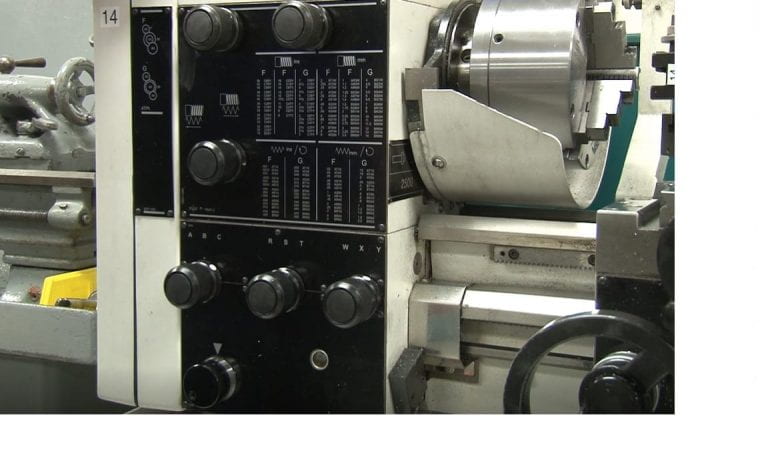

The lathe information on the page is to help you with aspects of the operation of each piece of equipment. Many of the videos are meant to help you remember and reinforce what you have learned in the MEMS 1001 class. As always, if you need additional training on equipment, reach out to the instructors to arrange for in-person training.